AUTODockit - Top 7 FAQs

1. How many boats can an AUTODockit System store as compared to a conventional approach?

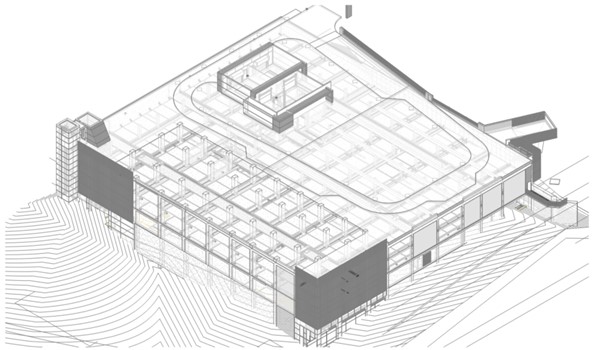

The AUTODockit System increases storage capacity from 65% to 100% compared to a traditional approach. It features a modular and scalable architecture made from structural steel. The system can be well over 200 feet tall and implemented on sites ranging from multiple acres to as small as half an acre.

2. What are the boat sizes and weights supported by AUTODockit?

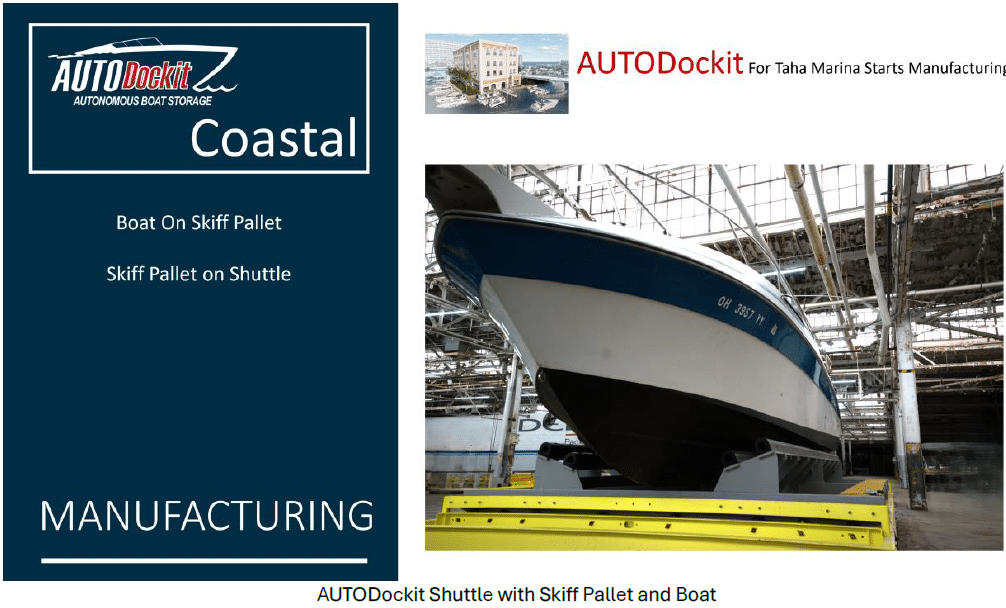

AUTODockit Costal System standard is built for boats between 25 and 55 feet in length overall (LOA). AUTODockit Costal can be customized for longer boats. The standard maximum weight of a boat is 40,000 pounds. AUTODockit Costal can be customized for heavier boats.

3. What does the AUTODockit System Cost?

Pricing for the AUTODockit System is based on (i) the density of dry berths, (ii) boat size mix, and (iii) system options. One popular option is the integration of autonomous vehicle parking via AUTOParkit.

4. How quickly can a boat be retrieved from storage and launched?

AUTODockit is designed to store and retrieve boats in less than 5 minutes. This is accomplished through

concurrency of movement, enabling multiple boats to be moved simultaneously throughout the entire system. Separate equipment is used for vertical and horizontal movement, which simplifies the overall system for both operation and maintenance.

5. How does the AUTODockit System Achieve Reliability?

AUTODockit is designed, built, and maintained using a comprehensive multifaceted layered strategy to achieve 100% uptime. Below is a short list of some of the techniques employed:

MTBF – Mean Time Between Failure. All major pieces of equipment are tracked for end-of-life. Use of electric motors. Electric motors do not simply fail, they fail over a long period. Collecting data on the motor’s performance and applying analytics allows for “predictive failure” so equipment can be replaced long before it impacts the system’s performance.

MTTR – Mean Time To Repair. Simply put, if something breaks, how long does it take to repair it? We keep spare parts on-site so a technician can replace them quickly and efficiently.

No Single Point Of Failure — This is part of our design philosophy, so we build into the AUTODockit System (i) backup methods (e.g. onsite generator for power), (ii) automatic retries, and (iii) self-diagnostics reported via custom SCADA software.

6. How is an AUTODockit System Maintained?

GarageFloor24 (GF24), a Division of Dasher Lawles, offers a 24-hour monitoring service stationed at a Remote Operation Center (ROC) and on-site maintenance services for the entire system.

7. Does AUTODockit Support Trailered Boats?

AUTODockit Inland provides a drive-through Load Bay that accepts trailered boats. The boat trailer is unhitched while it resides in the Load Bay and then securely attached to an AUTODockit Pallet. It is then automatically transported into the AUTODockit Rack Storage structure. When the owner requests their boat, it is delivered to a Load Bay. The driver simply backs up their vehicle to the Load Bay and hitches the boat trailer.

Conversely, AUTODockit Coastal lifts the vessel directly from a wet slip equipped with a Dock Lift and a submerged Skiff Pallet. Once your boat is cradled on a Skiff Pallet it is safely transported into the AUTODockit Rack Storage structure.

Thank you for reading this newsletter. If you have any further questions or are interested in AUTODockit, please contact:

Shawn Adams, the EVP of Sales

sadams@dasherlawless.com

M 630.310.1902