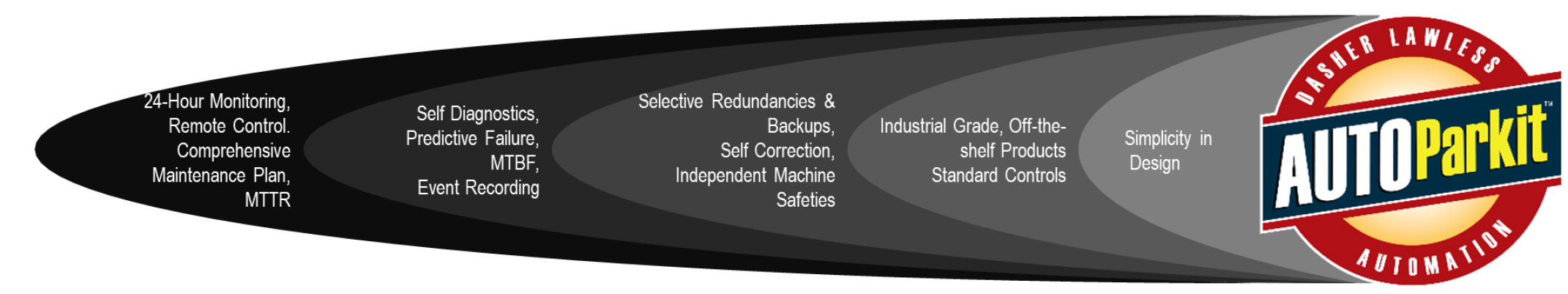

A Comprehensive Multifaceted Layered Strategy

AUTOParkit was conceived using a holistic approach governed by our guiding principles for the entire product life-cycle and employee an innovative design, industrial rated components, extensively tested software, and proven process techniques to ensure 99.99% reliability. A comprehensive multifaceted layered strategy sets the foundation that deliveries system reliability.

Each Facet Adds Additional Protection to the AUTOParkit System

AUTOParkit Guiding Principles

- Safe – It is first and foremost for every interaction, during every phase for the entire life-cycle of the AUTOParkit System

- Modularity and Scalability – Allow for multiple combinations based on the same set of welldefined subsystems. There must be two essential elements to achieve modularity: (1) A thoroughly defined specification for external interfaces/behavior and (2) enforcement of that specification

- Simple – Each installation includes the principle that a system is simple when based on a welldefined, straightforward, consistent set of rules

- Robust – Capable of running 24/7/365 and providing MTBF with proper maintenance for over ten years

- Cost-Effective – Each installation shall be less than or equal to an equivalent traditional parking structure. Operating costs shall be 40% less than a conventional brick and mortar parking structure.

- Performance – Peak-Hour-Demand of retrieval or storage shall remain the benchmark for each system. An AUTOParkit System shall be capable of delivery of a vehicle in 40 to 180 seconds.

- Engineered – Works as designed. It is not by fate, luck, fortune, or wishful thinking but by purposeful planning, meticulous design, and careful implementation.

AUTOParkit’s Multi…

Inherent in the AUTOParkit design process is continuous mitigation against a single point of failure. This is not only for the build process but also for operations.

AUTOParkit Multi-Path: AUTOParkit automatically selects an alternate route due to congestion or maintenance when delivering a vehicle. It continuously recalculates the ETA of each possible path and can choose an alternate path at any time.

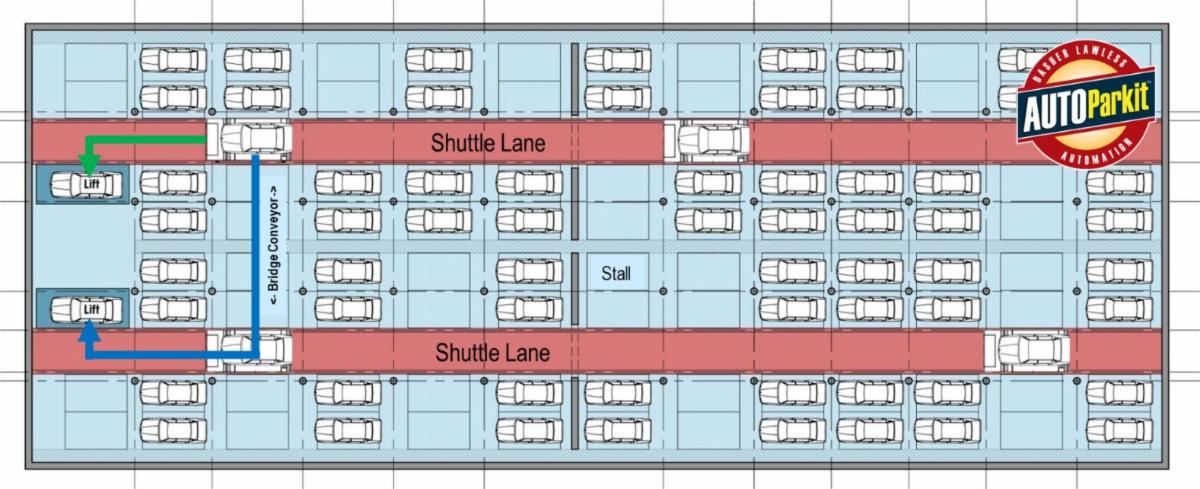

In the diagram below, GREEN is the primary path and BLUE is the secondary path. This design does not rely on a single route for vehicle delivery.

Reliability Examples: (1) Multi-Path & (2) Multiple Shuttles / Shuttle Lane

AUTOParkit Multi-Shuttle: Also shown in the diagram above is the ability for AUTOParkit to be designed with multiple Shuttles in the same Shuttle Lane. This provides increased performance and improves system reliability.

AUTOParkit Reliability Additional Examples

AUTOParkit spans architectural, structural, mechanical, electrical, logical, and even virtual systems. System reliability is accomplished using a variety of proven and innovative techniques. Below is a select list of inherent techniques deployed by every AUTOParkit System.

Design/Build

- Pallets are powder-coated on all six sides

- Rollers built for more than 1,000,000 Revolutions

- Integrated intelligence with self-correcting features

- Distributed Controls

- Use of parasitic drives to reduce system costs

Industrial Grade Components

- IP66 Rated Control Panels

- IP67 Rated Motors

24 Hour – Monitoring

- Monitoring Service Plan (MSP) for 24/7 System Monitoring and online support

- Self Diagnostics with automated reporting

- HD Cameras for immediate remote visualizations

Scheduled Maintenace

- Maintenance Service Agreement (MSA) for monthly scheduled maintenance

Predictive Maintenance

- MTBF – End of life for critical components are track

- On-site spare parts reduce MTTR

Select Redundancies/Backup

- UPS

- Multiple LANs

- Dual Electric Motors for Lifts

For more information on AUTOParkit, visit www.autoparkit.com.

Follow on Instagram:

Lawless Alan / @lawless_alan

Dasher Lawless Racing / @dasherlawlessracing

For media requests, please contact Shawn Adams at:

sadams@dasherlawless.com

C 630.310.1902