In nearly every conversation with a commercial developer, they typically use the phrase, Robotic Parking when referring to an automated parking system (APS). The reality is that AUTOParkit does NOT use robots to park vehicles, unlike other providers of an APS.

Why not use robotic control? Robots are used when machine precision and movement complexity are required. Automated parking of vehicles requires much larger tolerances than the precision and sophistication offered by Robotic Control allows.

Robots are not required for Automated Parking Systems

Machine Tolerance vs. Building Tolerance

Precision is relative. This notion is critical to understanding the parking application to avoid over-engineering the end solution. Robotic precision can be down to the millimeter (1 millimeter = 0.0393701 inches). Think of robots used in surgery, robotic welders, or robotic assembly to pick up parts from a moving conveyor; these all use +/- millimeters tolerances. In broader terms, there is a considerable difference between Machine Tolerance and Building Tolerance. Building Tolerance is an entirely different animal. The acceptable building tolerance for floor height variation of a raised concrete slab over 20 linear feet is ½” and could be as much as ¾” – 1″ in certain instances.

Additionally, the live load, or the number of cars in this example, on a floor can change the camber or flatness of a raised concrete slab by inches. This deflection can easily knock a robot out of tolerance, causing chronic performance issues. Another consideration is the fact that buildings move and are designed that way purposely. Yes, sometimes hard to imagine that a massive skyscraper sways back and forth in the wind by 3 or 4 feet. Steel and concrete expand and contract depending on temperature, direct sunlight, wind, rain, etc., which needs to be accounted for in the parking system design. These factors require consideration when selecting the mechanical type and control architecture for an automated parking system. So it’s imperative when considering an APS that the system is designed to work within building tolerances of +/- multiple inches and not machine tolerances of millimeters. Typically these application characteristics are not a good recipe for Robotic Control.

Total Cost of Ownership

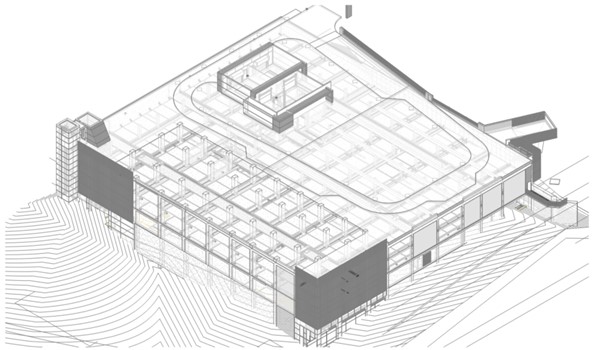

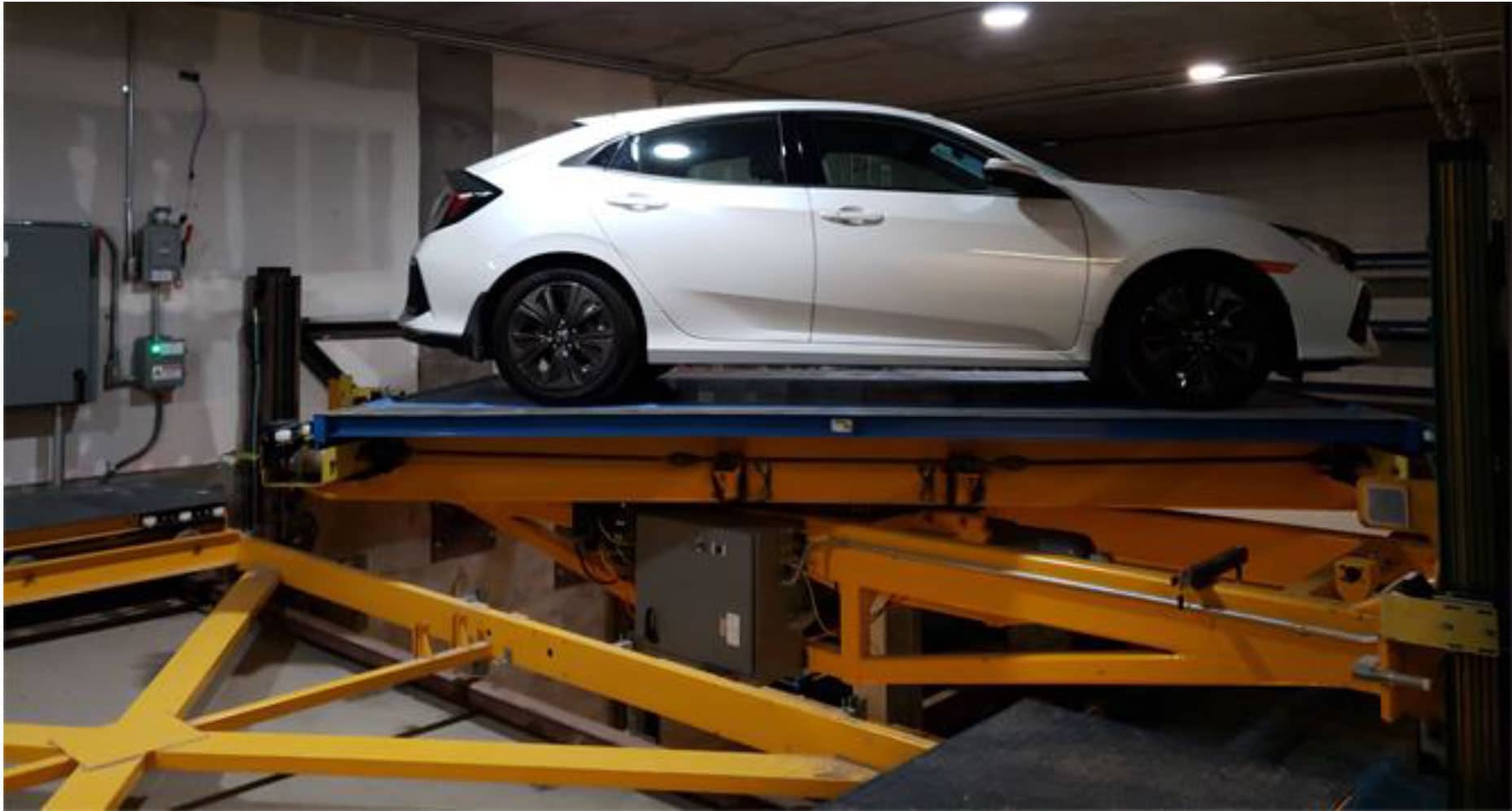

AUTOParkit uses a rack & rail system that leverages bolt and frame steel columns and beams. The vehicles are moved on individual steel platforms called pallets. The control system uses standard Programmable Logic Controler (PLC ), which are ubiquitous in industrial controls. Since most control engineers have experience with PLCs, they would find themselves more than capable of supporting an AUTOParkit System. The same could not be said for robotic controls.

After the Vehicle is CONVEYED to a Lift, it is ROTATED when the Lift is at the rotational level

The AUTOParkit System uses standard controls with off-the-shelf components and electric AC Motors that reduce the total cost of ownership. Robots use DC brushless Motors with Servo Drives due to the precision required. DC motor costs are more than double the equivalent AC motor. DC motors are only competitive in cost for single horsepower and below. Unfortunately, to move a 6,000-pound vehicle requires more than a single horsepower motor. The AC motors deployed by AUTOParkit range from 3 to 50 HP.

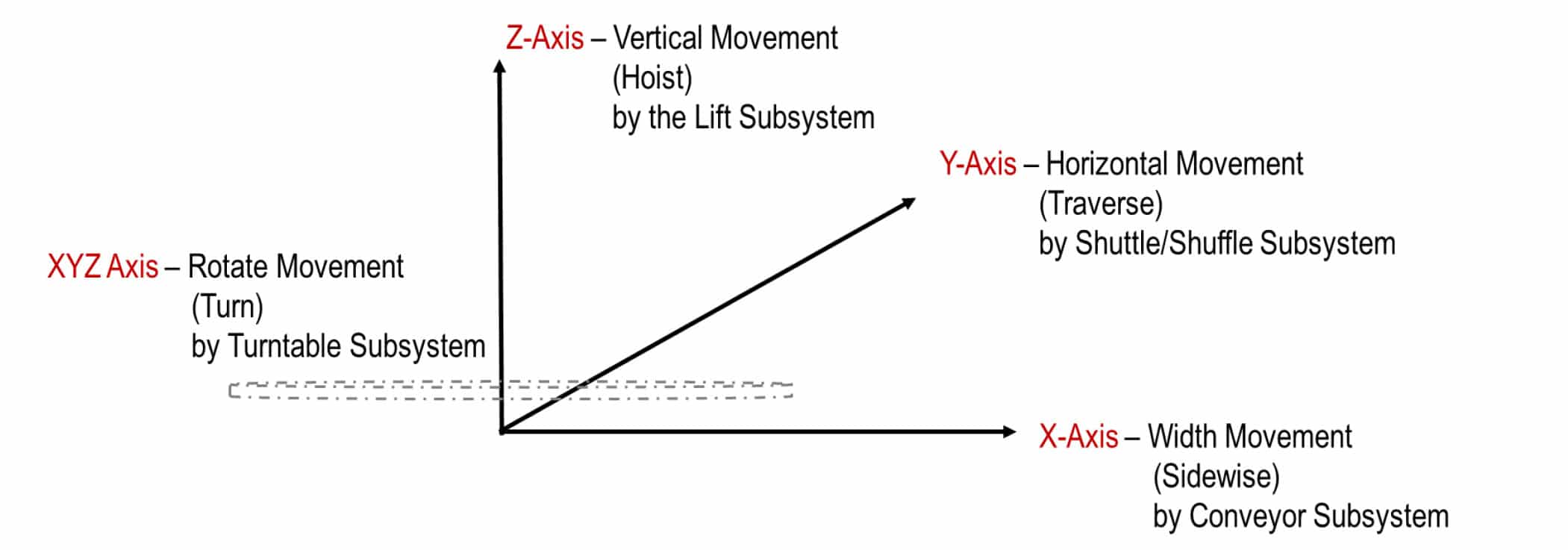

Number of Axes

AUTOParkit is built from concurrency of movement. Each subsystem runs independently of all other subsystems and synchronizes exchanges between multiple subsystems. When witnessing this operation live, it provides the illusion of robotic control, but upon closer inspection, each subsystem is only dealing with a single axis at a time. Robotic control is typically involved with coordinating multiple axes simultaneously and subsequently more complex movements, e.g., curves. AUTOParkit movement is a linear point-to-point motion instead of Robotic Control with simultaneous multi-axis, precision path control. The most complex movement performed by AUTOParkit is rotating a vehicle 180°.

Summary

Parking vehicles require simple linear movement (one axis at a time) with building tolerances measured in ¼ to ½ inches and a machine the size of a building. Lowering the total cost of ownership is achieved by deploying 3, 7, and 50 HP AC motors which are half the cost of an equivalent DC motor.

We deploy basic controls experience with PLCs, more prevalent than Robotic Control, and standard off-the-shelf electrical components from Siemens available worldwide from any authorized distributor.

If you need information, don’t hesitate to get in touch with us.

For more information on AUTOParkit, visit www.autoparkit.com.

Follow on Instagram:

Lawless Alan / @lawless_alan

Dasher Lawless Racing / @dasherlawlessracing

For media requests, please contact Shawn Adams at:

sadams@dasherlawless.com

C 630.310.1902